Fasaha Hakowa Laser- Dole ne na kera allon PCB HDI

An buga: Yuli 7, 2022

Rukunin:Blogs

Tags: PCB, PCB Fabrication, PCB na ci gaba, HDI PCB

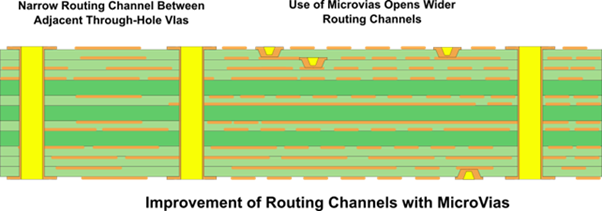

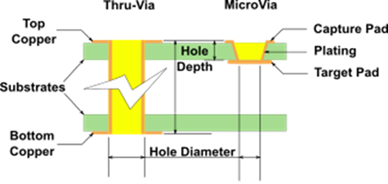

Microviasana kuma kiran su makafi via-ramuka (BVHs) a cikibuga allon kewayawa(PCBs) masana'antu.Manufar waɗannan ramukan shine don kafa haɗin lantarki tsakanin yadudduka akan multilayerallon kewayawa.Lokacin da kayan lantarki suka tsara taFasahar HDI, microvias babu makawa ana la'akari da su.Ikon sanya ko dai a kan ko a kashe pads yana ba masu zanen sassauci don zaɓar sararin samaniya a cikin sassa masu yawa na ma'aunin, saboda haka,PCB allongirman za a iya raguwa sosai.

Ga masu kera PCB na allunan HDI, rawar laser shine mafi kyawun zaɓi don hako madaidaicin microvias.Waɗannan microvias ƙanana ne kuma suna buƙatar hakowa zurfin sarrafawa daidai.Yawanci ana iya samun wannan madaidaicin ta hanyar leza drills.Laser hakowa shine tsarin da ke amfani da makamashi mai mahimmanci na Laser don hakowa (vaporizing) rami.Laser hakowa yana haifar da madaidaicin ramuka akan allon PCB don tabbatar da daidaito koda lokacin da ake mu'amala da mafi ƙarancin girma.Lasers na iya haƙa 2.5 zuwa 3-mil vias akan ƙaramin lebur gilashin ƙarfafawa.A cikin yanayin rashin ƙarfi na dielectric (ba tare da gilashi ba), yana yiwuwa a yi amfani da 1-mil vias ta amfani da laser.Don haka, ana ba da shawarar hakowa ta Laser don hako microvias.

Ko da yake za mu iya yin rawar soja ta hanyar ramukan diamita na mil 6 (0.15 mm) tare da raƙuman rawar soja na inji, farashin kayan aiki yana ƙaruwa sosai yayin da ƙananan raƙuman ruwa na bakin ciki suna karye cikin sauƙi, kuma suna buƙatar sauyawa akai-akai.Idan aka kwatanta da hakowa na inji, amfanin hakowar Laser an jera su a ƙasa:

- Tsarin hanyar sadarwa ba:Laser hakowa tsari ne gaba daya ba lamba sabili da haka lalacewar da aka jawo a kan rawar soja da kuma abu ta hanyar hakowa vibration an shafe.

- Madaidaicin iko:Ƙarfin katako, fitarwar zafi, da tsawon lokacin katako na laser suna ƙarƙashin iko don fasahar hakowa na Laser, don haka wanda ke taimakawa wajen kafa siffofi daban-daban tare da daidaitattun daidaito.Wannan haƙuri ± 3 mil kamar yadda matsakaicin ya kasance ƙasa da hakowa na inji tare da haƙurin PTH ± 3 mil da haƙurin NPTH na ± 4 mil.Wannan yana ba da damar samuwar makafi, binne, da tashe ta hanyar ƙera allunan HDI.

- Rabo mai girma:Ɗaya daga cikin mahimman ma'auni na ramin da aka toshe akan allon da'irar da aka buga shi ne yanayin yanayin.Yana wakiltar zurfin rami zuwa diamita ta hanyar.Tun da lasers na iya haifar da ramuka tare da ƙananan diamita yawanci jere daga mil 3-6 (0.075mm-0.15mm), suna ba da babban al'amari rabo.Microvia yana da bayanin martaba daban-daban idan aka kwatanta da na yau da kullun ta hanyar, yana haifar da rabo na daban.Microvia na yau da kullun yana da yanayin rabo na 0.75:1.

- Mai tsada:Laser hakowa ne muhimmanci sauri fiye da inji hakowa, ko da don hakowa densely sanya vias a multilayer jirgin.Bugu da ƙari, yayin da lokaci ya wuce, ƙarin farashi daga maye gurbin raguwar rawar jiki akai-akai yana ƙaruwa kuma hakowa na inji na iya zama mafi tsada idan aka kwatanta da hakowa na Laser.

- Ayyuka da yawa:Hakanan ana iya amfani da na'urorin Laser da ake amfani da su don hakowa don sauran hanyoyin masana'antu kamar walda, yankan, da sauransu.

PCB masana'antunsuna da zaɓuɓɓukan laser iri-iri.PCB ShinTech yana ƙaddamar da infrared da ultraviolet lasers don hakowa yayin yin PCBs HDI.Haɗin Laser daban-daban suna da mahimmanci kamar yadda masana'antun PCB ke amfani da kayan wuta da yawa kamar guduro, ƙarfafa prepreg, da RCC.

Ƙarfin katako, fitarwar zafi, da tsawon lokacin katako na laser ana iya tsara shi a ƙarƙashin yanayi daban-daban.Ƙarƙashin ƙaƙƙarfan katako na iya haƙowa ta hanyar kayan halitta amma suna barin karafa ba tare da lahani ba.Don yanke ta ƙarfe da gilashi, muna amfani da katako mai ƙarfi.Yayin da ƙananan ƙananan igiyoyi na buƙatar katako na 4-14 mil (0.1-0.35 mm) diamita, ƙananan igiyoyi suna buƙatar katako na kimanin mil 1 (0.02 mm).

Kamfanin masana'antu na PCB ShinTech ya tara fiye da shekaru 15 gwaninta a cikin sarrafa Laser kuma ya tabbatar da rikodin nasara a cikin wadatar HDI PCB, musamman a cikin ƙirar PCB mai sassauƙa.An ƙera mafitarmu don samar da amintattun allunan kewayawa da sabis na ƙwararru tare da farashi mai gasa don tallafawa ra'ayoyin kasuwancin ku cikin kasuwa yadda ya kamata.

Da fatan za a aiko da tambayarku ko buƙatar faɗi mana asales@pcbshintech.comdon haɗawa da ɗaya daga cikin wakilan tallace-tallacenmu waɗanda ke da ƙwarewar masana'antu don taimaka muku samun ra'ayin ku zuwa kasuwa.

Idan kuna da wasu tambayoyi ko buƙatar ƙarin bayani, jin daɗin kiran mu a+ 86-13430714229koTuntube Mu on www.pcbshintech.com.

Lokacin aikawa: Jul-10-2022