Yadda Ake Zaɓan Ƙarshen Surface don Ƙirar PCB ɗinku

Ⅲ Jagorar zaɓe da abubuwan haɓakawa

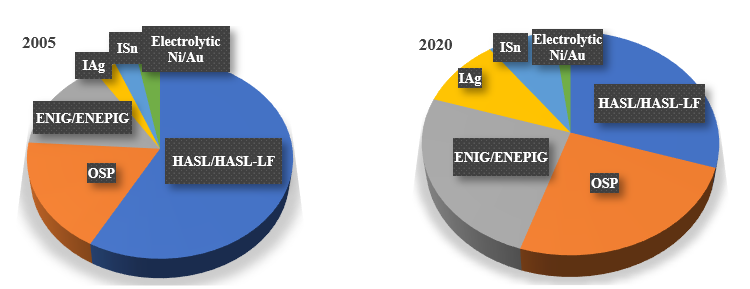

Kamar yadda aka nuna a sama ginshiƙi, PCB surface gama aikace-aikace sun bambanta magnificently a cikin past 20 shekaru kamar yadda fasaha tasowa da gaban muhalli-friendly kwatance.

1) HASL Gubar Kyauta.Kayan lantarki sun ragu sosai a cikin nauyi da girma ba tare da sadaukar da aiki ko aminci a cikin 'yan shekarun nan ba, wanda ya iyakance amfani da HASL zuwa babban abin da ba shi da daidaituwa kuma bai dace da farati mai kyau ba, BGA, ƙananan abubuwan da aka sanya da kuma sanya su cikin ramuka.Ƙarewar matakin iska mai zafi yana da babban aiki (abin dogaro, solderability, masaukin zagayowar zafin jiki da yawa da tsawon rayuwar shiryayye) akan taron PCB tare da manyan gammaye da tazara.Yana ɗaya daga cikin mafi araha da samuwa gama.Kodayake fasahar HASL ta samo asali zuwa sabon ƙarni na ba da izini na HASL don bin ƙa'idodin RoHS da umarnin WEEE, ƙarshen matakin iska mai zafi ya faɗi zuwa 20-40% a cikin masana'antar ƙirƙira PCB daga kasancewa mamaye (3/4) wannan yanki a cikin 1980s.

2) OSP.OSP ya shahara saboda mafi ƙarancin farashi da tsari mai sauƙi da samun pads ɗin haɗin gwiwa.Har yanzu ana maraba saboda wannan.The Organic shafi tsari za a iya amfani da ko'ina duka a kan daidaitattun PCBs ko ci-gaba PCBs kamar lafiya farar, SMT, bauta alluna.Sabuntawar kwanan nan ga farantin multilayer na shafaffen kwayoyin halitta sun tabbatar da cewa OSP ya tsaya tsayin daka na siyarwa.Idan PCB ba shi da buƙatun aikin haɗin ƙasa ko iyakancewar rayuwa, OSP zai zama mafi kyawun tsarin gamawa.Duk da haka kurakuran sa, da hankali ga lalacewa, gajeriyar rayuwar shiryayye, rashin ɗabi'a da wahalar dubawa yana rage matakinsa don ya zama mai ƙarfi.An kiyasta cewa kimanin kashi 25% -30% na PCBs a halin yanzu suna amfani da tsarin shafan kwayoyin halitta.

3) ENIG.ENIG shine mafi mashahurin gamawa tsakanin PCBs masu ci gaba da PCBs da aka yi amfani da su a cikin yanayi mai tsauri, saboda kyakkyawan aikin sa akan shimfidar tsari, solderability da karko, juriya ga lalata.Yawancin masana'antun PCB suna da layukan gwal na nickel / nutsewa maras amfani a cikin masana'antar allunan da'ira ko taron bita.Ba tare da la'akari da farashi da sarrafa tsari ba, ENIG zai zama mafi kyawun zaɓi na HASL kuma yana da ikon amfani da ko'ina.Zinariya maras amfani da nickel/ nutsewa yana girma cikin sauri a cikin 1990s saboda warware matsalar daidaitawar iska mai zafi da kawar da ruwa mai rufaffiyar jiki.ENEPIG azaman sabon sigar ENIG, ya warware matsalar kushin baƙar fata na nickel / nutsewar zinari amma yayin da yake da tsada.Aikace-aikacen ENIG yana ɗan raguwa kaɗan tun tashin farashin ƙarancin canji kamar Immersion Ag, Immersion Tin da OSP.An kiyasta kusan kashi 15-25% na PCBs a halin yanzu sun karɓi wannan gamawa.Idan babu haɗin kai na kasafin kuɗi, ENIG ko ENEPIG shine kyakkyawan zaɓi akan mafi yawan yanayi musamman ga PCBs tare da buƙatun buƙatu na inshorar inganci, fasahar fakitin hadaddun, nau'ikan siyarwa da yawa, ramuka, haɗin waya, da latsa fit fasaha, da dai sauransu.

4) Azurfa nutsewa.A matsayin mai rahusa musanyawa na ENIG, azurfa nutsewa yana da kaddarorin samun fage mai faɗi, babban aiki mai ƙarfi, matsakaicin rayuwar shiryayye.Idan PCB ɗin ku yana buƙatar farar farar kyau / BGA SMT, ƙananan abubuwan haɗin gwiwa, kuma yana buƙatar ci gaba da aikin haɗin kai yayin da kuke da ƙarancin kasafin kuɗi, azurfa nutsewa shine zaɓi mafi kyau a gare ku.Ana amfani da IAg ko'ina a cikin samfuran sadarwa, motoci, da na'urorin kwamfuta, da dai sauransu. Saboda aikin wutar lantarki da bai dace da shi ba, ana maraba da shi cikin ƙira mai girma.Girman azurfar nutsewa yana jinkirin (amma har yanzu yana tashi) saboda fa'idodin kasancewa masu hankali don ɓarna da samun ɓarna na haɗin gwiwa.Akwai kusan 10% -15% na PCBs a halin yanzu suna amfani da wannan ƙarewa.

5) Tin nutsewa.An gabatar da Tin Immersion a cikin aikin gamawa sama da shekaru 20.Samar da aiki da kai shine babban direba na gamawar saman ISn.Wani zaɓi ne mai tsada don buƙatun shimfidar shimfidar wuri, wuri mai kyau na abubuwan haɗin ginin da latsa-fit.ISn ya dace musamman don jiragen baya na sadarwa don babu wani sabon abubuwa da aka ƙara yayin aikin.Tin Whisker da gajeriyar taga aiki shine babban iyakancewar aikace-aikacen sa.Ba a ba da shawarar nau'in haɗuwa da yawa ba idan aka ba da haɓakar Layer na ƙarfe yayin siyarwa.Bugu da ƙari, an hana yin amfani da tsarin nutsar da tin saboda kasancewar carcinogens.An kiyasta cewa kusan 5% -10% na PCBs a halin yanzu suna amfani da tsarin tin na nutsewa.

6) Electrolytic Ni/Au.Electrolytic Ni/A shine mafarin fasahar jiyya na PCB.Ya bayyana tare da gaggawa na bugu na allon kewayawa.Koyaya, tsada mai tsada sosai yana iyakance aikace-aikacen sa.A zamanin yau, Soft zinare galibi ana amfani da ita don waya ta gwal a cikin marufi;Ana amfani da zinari mai ƙarfi musamman don haɗin kai na lantarki a wuraren da ba a sayar da su kamar yatsun zinare da masu ɗaukar IC.Matsakaicin Electroplating Nickel-gold yana kusan 2-5%.

Bayazuwa Blogs

Lokacin aikawa: Nuwamba-15-2022