An buga: Fabrairu 15, 2022

Rukunin:Blogs

Tags:pcb, pcbs, pcba, pcb taro, smt, stencil

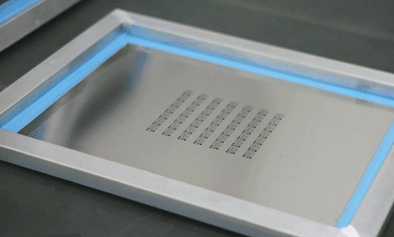

Menene PCB Stencil?

PCB Stencil, kuma aka sani da Karfe raga, takarda ce ta stai

nless karfe tare da Laser yanke budewa amfani don canja wurin wani m adadin solder manna zuwa wani m sanya matsayi a kan danda PCB ga surface Dutsen aka gyara jeri.A stencil ya ƙunshi firam ɗin stencil, ragar waya da takardar ƙarfe.Akwai ramuka da yawa a cikin stencil, kuma matsayi na waɗannan ramukan sun dace da matsayin da ake buƙatar buga akan PCB.Babban aikin stencil shine a ajiye daidai adadin manna mai siyar akan gammaye domin haɗin haɗin siyar tsakanin kushin da ɓangaren ya zama cikakke dangane da haɗin lantarki da ƙarfin injina.

Lokacin amfani, sanya PCB a ƙarƙashin stencil, Da zarar

stencil yana daidaita daidai a saman allon, ana amfani da manna solder akan buɗewar.

Sa'an nan kuma manna solder yana leaked zuwa saman PCB ta cikin ƙananan ramuka a kafaffen matsayi akan stencil.Lokacin da foil ɗin ƙarfe ya rabu da allon, manna mai siyarwa zai kasance a saman allon kewayawa, a shirye don sanya na'urorin hawan saman saman (SMDs).Ƙarƙashin manna mai siyar da aka toshe akan stencil, yawancin ana ajiye shi akan PCB.Ana iya maimaita wannan tsari daidai, don haka yana sa tsarin SMT ya fi sauri da daidaito kuma yana tabbatar da ƙimar PCB Majalisar.

Menene PCB Stencil da aka yi dashi?

A SMT stencil an yi shi da firam ɗin stencil, raga da

bakin karfe, da manne.Firam ɗin stencil ɗin da aka fi amfani dashi shine firam ɗin da aka makale akan ragar waya tare da manne, wanda ke da sauƙin samun tashin hankali na ƙarfe na ƙarfe, wanda shine gabaɗaya 35 ~ 48N / cm2.raga shine don gyara takardar karfe da firam.Akwai nau'ikan raga guda biyu, ragar bakin karfe na waya da ragar polyester polymer.Na farko zai iya ba da kwanciyar hankali da isasshen tashin hankali amma mai sauƙin lalacewa da lalacewa.Daga baya duk da haka na iya dadewa idan aka kwatanta da bakin karfe waya raga.Gabaɗaya takardar stencil ɗin da aka karɓa shine takardar bakin karfe 301 ko 304 wanda a bayyane yake inganta aikin stencil ta hanyar ingantattun kayan aikin injin sa.

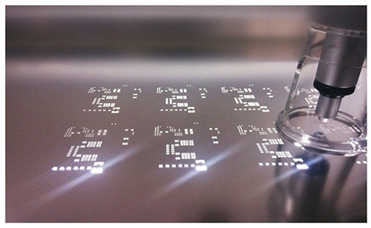

Hanyar masana'anta na Stencil

Akwai nau'ikan stencil guda bakwai da kuma hanyoyi guda uku don kera stencils: etching chemical, yankan Laser da electroforming.Kullum ana amfani da shi ne Laser karfe stencil.Las

er stencil shine mafi yawan amfani dashi a masana'antar SMT, wanda ke da alaƙa shine:

Ana amfani da fayil ɗin bayanan kai tsaye don rage kuskuren masana'anta;

Matsayin buɗewa daidaito na SMT stencil yana da girma sosai: duk kuskuren tsari shine ≤± 4 μ m;

Bude stencil na SMT yana da ilimin lissafi, wanda shine conduci

ve ga bugu da gyare-gyare na solder manna.

Laser sabon tsari kwarara: fim yin PCB, shan daidaitawa, data fayil, data aiki, Laser sabon, nika.Tsarin yana tare da daidaitattun samar da bayanai da ƙananan tasiri na dalilai masu mahimmanci;Buɗewar trapezoidal yana dacewa da lalatawa, ana iya amfani dashi don yankan madaidaici, arha farashin.

Gaba ɗaya buƙatun da ƙa'idodin PCB Stencil

1. Don samun cikakken bugu na solder manna a kan PCB gammaye, da takamaiman matsayi da ƙayyadaddun zai tabbatar da high bude daidaito, da kuma bude zai kasance a cikin m daidai da ƙayyadadden hanyar budewa ake magana a kai ga fiducial alamomi.

2. Don guje wa lahani na siyarwa kamar gada da beads, buɗaɗɗen buɗewa mai zaman kanta za a tsara ɗan ƙarami fiye da girman kushin PCB.jimlar fadin kada ya wuce 2mm.Yankin kushin PCB ya kamata koyaushe ya zama mafi girma fiye da kashi biyu bisa uku na yanki na cikin bangon buɗaɗɗen stencil.

3. Lokacin shimfiɗa raga, sarrafa shi sosai, da pa

y kulawa ta musamman ga kewayon buɗewa, wanda dole ne ya kasance a kwance da tsakiya.

4. Tare da bugu surface a matsayin saman, ƙananan buɗaɗɗen raga zai zama 0.01mm ko 0.02mm mai faɗi fiye da budewa na sama, wato, budewa za a juya shi conical don sauƙaƙe ingantaccen saki na manna solder kuma rage tsaftacewa. lokaci na stencil.

5. Dole ne bangon raga ya zama santsi.Musamman ga QFP da CSP tare da tazarar ƙasa da 0.5mm, ana buƙatar mai siyarwa don gudanar da aikin lantarki yayin aikin masana'anta.

6. Gabaɗaya, ƙayyadaddun ƙayyadaddun buɗaɗɗen stencil da nau'ikan abubuwan SMT sun dace da kushin, kuma rabon buɗewa shine 1: 1.

7. Madaidaicin kauri na takardar stencil yana tabbatar da sakin

na adadin solder manna ta wurin budewa.Ƙarin ajiya na solder na iya haifar da gadar siyar yayin da ƙarancin ajiya zai haifar da raunin solder haɗin gwiwa.

Yadda za a zana PCB Stencil?

1. 0805 kunshin yana bada shawarar yanke pads biyu na budewa ta 1.0mm, sa'an nan kuma yin da'irar concave B = 2 / 5Y;A = 0.25mm ko a = 2/5 * l anti tin bead.

2. Chip 1206 da sama: bayan an motsa pads biyu zuwa waje ta 0.1mm bi da bi, yi da'irar concave na ciki B = 2 / 5Y;A = 2/5 * l maganin katako na tin.

3. Domin PCB tare da BGA, da bude rabo na stencil tare da ball tazarar fiye da 1.0mm ne 1: 1, da kuma bude rabo na stencil tare da ball tazara na kasa da 0.5mm ne 1: 0.95.

4. Ga duk QFP da SOP tare da 0.5mm farar, rati na buɗewa

o a cikin jimlar nisa shugabanci shine 1:0.8.

5. Matsakaicin budewa a cikin tsayin daka shine 1: 1.1, tare da 0.4mm QFP QFP, budewa a cikin dukkanin fadin nisa shine 1: 0.8, budewa a cikin tsayin daka shine 1: 1.1, da ƙafar zagaye na waje.radius chamfer r = 0.12mm.Jimlar faɗin buɗewar ɓangaren SOP tare da farar 0.65mm an rage shi da 10%.

6. Lokacin da PLCC32 da PLCC44 na samfuran gabaɗaya suka lalace, jimlar nisa shugabanci shine 1: 1 kuma tsayin shugabanci shine 1: 1.1.

7. Don na'urorin SOT na gaba ɗaya, rabon buɗewa

na babban kushin ƙarshen shine 1: 1.1, jimlar nisa shugabanci na ƙaramin kushin shine 1: 1, kuma tsayin shugabanci shine 1: 1.

YayaDon Amfani da PCB Stencil?

1. Karɓa da kulawa.

2. Za a tsaftace stencil kafin amfani.

3. Za a shafa man solder ko jan manne daidai gwargwado.

4. Daidaita bugun bugu zuwa mafi kyau.

5. Don amfani da bugu na pasteboard.

6. Bayan bugunan scraper, yana da kyau a tsaya na 2 ~ 3 seconds kafin a zubar, kuma saita saurin kashewa ba da sauri ba.

7. Stencil za a tsabtace a lokaci, adana da kyau bayan amfani.

Stencil Manufacture Service na PCB ShinTech

PCB ShinTech yana ba da sabis na kera bakin karfe na Laser.Muna yin stencil tare da kauri na 100 μm, 120 μm, 130µm, 150 μm, 180 μm, 200 μm, 250 μm da 300 μm.Fayil ɗin bayanan da ake buƙata don yin stencil na Laser dole ne ya ƙunshi SMT solder manna Layer, bayanan alamar aminci, Layer na PCB da ƙirar hali, don haka za mu iya bincika gaba da baya na bayanan, rukunin ɓangaren, da sauransu.

Idan kuna buƙatar fa'ida don Allah aika fayilolinku da bincike zuwasales@pcbshintech.com.

Lokacin aikawa: Juni-10-2022