Yin HDI PCB a cikin masana'antar PCB mai sarrafa kansa --- OSP saman gama

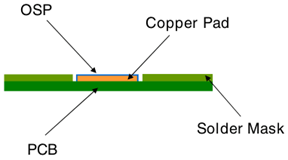

OSP yana tsaye ga Organic Solderability Preservative, wanda kuma ake kira da'irar jikin kwayoyin halitta ta masana'antun PCB, sanannen bugu ne na hukumar da'ira ta ƙare saboda ƙarancin farashi da sauƙin amfani don masana'antar PCB.

OSP yana amfani da sinadarai ta hanyar sinadarai zuwa filayen jan ƙarfe da aka fallasa yana ƙirƙirar ɗakuna masu zaɓi tare da tagulla kafin a sayar da shi, yana ƙirƙirar Layer ƙarfe don kare jan ƙarfe da aka fallasa daga tsatsa.Kauri OSP, bakin ciki ne, tsakanin 46µin (1.15µm) -52µin(1.3µm), wanda aka auna cikin A° (angstrom).

Kariyar Tsarin Tsarin Halitta a bayyane yake, da wahala don duba gani.A cikin siyarwar na gaba, za a cire shi da sauri.Ana iya amfani da tsarin nutsar da sinadarai ne kawai bayan an yi duk wasu matakai, gami da Gwajin Lantarki da Dubawa.Aiwatar da ƙarshen farfajiyar OSP zuwa PCB yawanci ya haɗa da hanyar sinadarai mai isarwa ko tankin tsoma tsaye.

Tsarin gabaɗaya yayi kama da haka, tare da rinses tsakanin kowane mataki:

1) Tsaftacewa.

2) Haɓakawa na Topography: Fuskar jan ƙarfe da aka fallasa yana fuskantar micro-etching don haɓaka haɗin gwiwa tsakanin hukumar da OSP.

3) Acid kurkura a cikin wani sulfuric acid bayani.

4) Aikace-aikacen OSP: A wannan lokacin a cikin tsari, ana amfani da maganin OSP akan PCB.

5) kurkura deionization: Ana shigar da maganin OSP tare da ions don ba da izinin kawar da sauƙi yayin siyarwa.

6) Dry: Bayan an gama amfani da OSP, dole ne a bushe PCB.

Ƙarshen OSP yana ɗaya daga cikin shahararrun ƙare.Yana da matukar tattalin arziƙi, zaɓi mai dacewa da muhalli don keɓan allunan da'ira bugu.Yana iya samar da co-planar pads surface for lafiya filaye/BGA/kananan abubuwan jeri.Fuskar OSP ana iya gyarawa sosai, kuma baya buƙatar kulawar kayan aiki mai girma.

Koyaya, OSP ba ta da ƙarfi kamar yadda ake tsammani.Yana da gazawarsa.OSP yana da kulawa don kulawa kuma yana buƙatar kulawa sosai don guje wa karce.Yawancin lokaci, ba a ba da shawarar sayar da abubuwa da yawa ba tunda Multiple soldering na iya lalata fim ɗin.Rayuwar shiryayyen sa ita ce mafi guntu a cikin duk abin da aka gama.Ya kamata a haɗa allunan nan da nan bayan yin amfani da sutura.A zahiri, masu samar da PCB na iya tsawaita rayuwar rayuwar sa ta hanyar sake gyara ƙarshen.OSP yana da matukar wahala a gwada ko dubawa saboda yanayin sa na gaskiya.

Ribobi:

1) Mara gubar

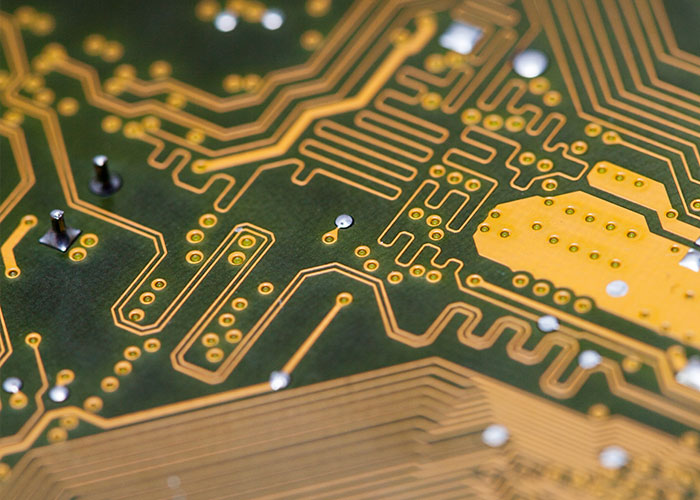

2) Flat surface, mai kyau ga m-fitch pads (BGA, QFP ...)

3) Shafi na bakin ciki sosai

4) Ana iya amfani da shi tare da sauran ƙare (misali OSP + ENIG)

5) Karancin farashi

6) Sake aiki

7) Tsari mai sauƙi

Fursunoni:

1) Ba shi da kyau ga PTH

2) Kula da Hankali

3) Short Shelf Life (<6 months)

4) Bai dace da fasahar crimping ba

5) Ba kyau ga mahara reflow

6) Copper za a fallasa a taro, yana buƙatar in mun gwada da m juzu'i

7) Wahalar dubawa, na iya haifar da matsala a gwajin ICT

Amfani na yau da kullun:

1) Na'urori masu kyau masu kyau: Wannan gamawa ya fi dacewa don amfani da na'urori masu kyau saboda rashin fakitin haɗin gwiwa ko saman da bai dace ba.

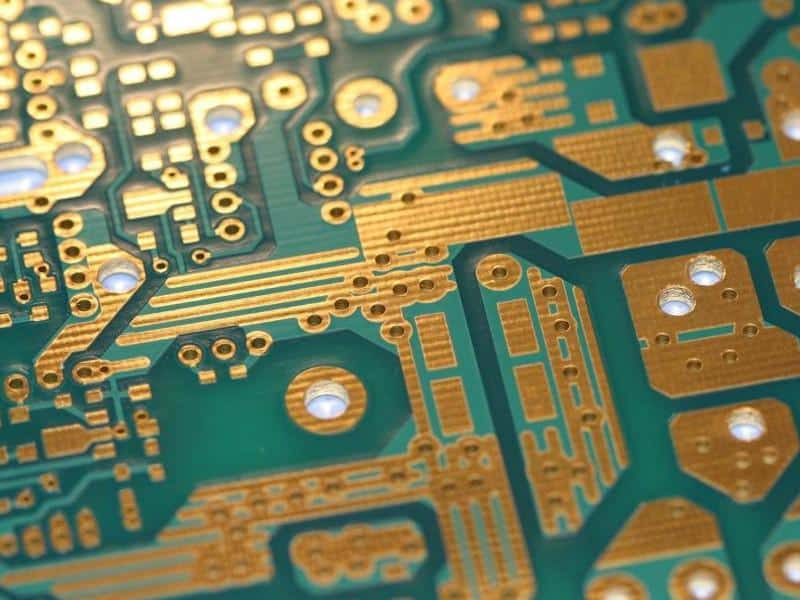

2) Allolin uwar garken: OSP yana amfani da kewayo daga ƙanana aikace-aikace zuwa babban allon sabar uwar garken.Wannan faffadan bambancin amfani yana sa ya dace da aikace-aikace da yawa.Ana kuma amfani da shi sau da yawa don kammala zaɓin zaɓi.

3) Fasaha Dutsen Surface (SMT): OSP yana aiki da kyau don taron SMT, don lokacin da kuke buƙatar haɗa wani abu kai tsaye zuwa saman PCB.

Bayazuwa Blogs

Lokacin aikawa: Fabrairu-02-2023