PCB Fabrication & PCB Assembly Capabilities

Kwamfutar Manufacturing PCB

| Abubuwa | Daidaitaccen PCB | PCB na ci gaba |

| Ƙarfin Ƙarfafawa | 40,000 m2kowane wata | 40,000 m2kowane wata |

| Layer | 1,2, 4, har zuwa 10 yadudduka | 1,2, 4, har zuwa 50 yadudduka |

| Kayan abu | FR-4, CEM-1, Aluminum, da dai sauransu. | FR-4 (Al'ada zuwa babban Tg), Babban CTI FR-4, CEM-1, CEM-3, Polymide (PI), Rogers, Glass Epoxy, Aluminum Base, Rohs Compliant, RF, da dai sauransu. |

| PCB irin | M | M, Mai sassauƙa, Mai ƙarfi-mai sassauƙa |

| Min.Babban Kauri | 4mil/0.1mm (2-12 Layer), 2mil/0.05mm (≥13 Layer) | 4mil/0.1mm (2-12 Layer), 2mil/0.06mm (≥13 Layer) |

| Nau'in Prepreg | 1080, 2116, 765-8, 106, 3313, 2165, 1500 | 1080, 2116, 765-8, 106, 3313, 2165, 1500 |

| Girman Hukumar Max | 26"*20.8" / 650mm*520mm | Mai iya daidaitawa |

| Kaurin allo | 0.4mm/16mil-2.4mm/96mil | 0.2mm/8mil-10.0mm/400mil |

| Hakuri mai kauri | ± 0.1mm (Kaurin allo <1.0mm);± 10% (Kauri na allo≥1.0mm) | ± 0.1mm (Kaurin allo <1.0mm);± 4% (Kauri na allo≥1.0mm) |

| Matsakaici mai girma | ± 0.13mm/5.2mil | ± 0.10mm/4 mil |

| Angle Warping | 0.75% | 0.75% |

| Kaurin Copper | 0.5-10 oz | 0.5-18 oz |

| Hakuri da Kauri na Copper | ± 0.25 oz | ± 0.25 oz |

| Min.Layi Nisa/Sarari | 4mil/0.1mm | 2 mil/0.05mm |

| Min.Diamita Ramin rami | 8mil/0.2mm (na inji) | 4mil/0.1mm (laser), 6mil/0.15mm (na inji) |

| PTH Kaurin bango | ≥18 μm | ≥20 μm |

| Haƙuri na PTH Hole | ± 3mil/0.076mm | ± 2mil/0.05mm |

| Haƙuri na NPTH Hole | ± 2mil/0.05mm | ± 1.5mil/0.04mm |

| Max.Halayen Rabo | 12:1 | 15:1 |

| Min.Makaho/An binne Ta | 4mil/0.1mm | 4mil/0.1mm |

| Ƙarshen Sama | HASL, OSP, Immersion Gold | HASL, OSP, Nickle, Immersion Gold, Imm Tin, Imm Silver, da dai sauransu. |

| Solder Mask | Kore, Ja, Fari, Yellow, Blue, Black | Kore, Ja, Fari, Yellow, Blue, Black, Orange, Purple, da dai sauransu. Mai iya canzawa |

| Solder Mask diyya | ± 3mil/0.076mm | ± 2mil/0.05mm |

| Launin siliki | Kore, Ja, Fari, Yellow, Blue, Black | Green, Blue, Black, White, Red, Purple, Transparent, Grey, Yellow, Orange, da dai sauransu. Customizable |

| Silkscreen Min.Nisa Layi | 0.006" ko 0.15mm | 0.006" ko 0.15mm |

| Sarrafa Impedance | ± 10% | ± 5% |

| Haƙuri na Wuri | ± 0.05mm, ± 0.13mm (2ndhuda rami zuwa 1stwurin rami) | ± 0.05mm, ± 0.13mm (2ndhuda rami zuwa 1stwurin rami) |

| PCB Yanke | Shear, V-Score, Tab-gudu | Shear, V-Score, Tab-gudu |

| Gwaje-gwaje da dubawa | AOI, Fly Probe Testing, ET gwajin, Microsection Inspection, Solderability Test, Impedance Test, da dai sauransu. | AOI, Fly Probe Testing, ET gwajin, Microsection Inspection, Solderability Test, Impedance Test, da dai sauransu. |

| Matsayin inganci | Babban darajar IPC II | IPC Class II, IPC Class III |

| Takaddun shaida | UL, ISO9001: 2015, ISO14001: 2015, TS16949: 2009, RoHS da dai sauransu. | UL, ISO9001: 2008, ISO14001: 2008, TS16949: 2009, AS9100, RoHS, da dai sauransu. |

PCB Majalisar Capabilities

| Ayyuka | Turnkey-daga masana'anta alluna, Samar da na'ura, taro, fakiti, bayarwa;Kitted/bangaran turkey-bangaren matakai na jeri na sama bisa ga buƙatun abokin ciniki. |

| Kayayyakin aiki | 15 na cikin gida SMT Lines, 3 a cikin gida ta hanyar-rami Lines, 3 a cikin-gidan karshe layukan taro |

| Nau'ukan | SMT, Thru-rami, Mixed (SMT/Thru-rami), Single ko biyu wuri jeri |

| Lokacin Jagora | Quickturn, Prototype ko ƙananan adadin: 3-7 kwanakin aiki (duk sassan suna shirye).Tsarin taro: 7-28 kwanakin aiki (duk sassan suna shirye);Akwai isar da aka tsara |

| Gwaji akan Samfura | Binciken X-ray, ICT (Gwajin Cikin-Circuit), 100% BGA X-Ray Inspection, Gwajin AOI (Dubawar gani Mai sarrafa kansa), Gwajin Jig/Mold, Gwajin Aiki, Binciken Fayil na jabu (na nau'in taro na kitted), da sauransu. |

| Bayanan PCB | M, Ƙarfe Core, Mai sassauƙa, Flex-Rigid |

| Yawan | MOQ: 1 pc.Samfurin, ƙaramin tsari, samar da taro |

| Sayen Sassa | Turnkey, Kitted/ Partial Turnkey |

| Stencials | Laser yanke bakin karfe |

| Ana samun suturar Nano | |

| Nau'in siyarwa | Jagoranci, mara gubar, Mai yarda da RoHS, mara tsafta da tsaftataccen ruwa |

| Ana Bukatar Fayiloli | PCB: Fayilolin Gerber (CAM, PCB, PCBDOC) |

| Abubuwan: Bill na Materials (Jerin BOM) | |

| Majalisar: Zaɓi & Wuri fayil | |

| Girman Kwamitin PCB | Min.Girma: 0.25*0.25 inci (6mm*6mm) |

| Matsakaicin girman: 48*24 inci (1200mm*600mm) | |

| Cikakkun bayanai | Mai wucewa zuwa girman 01005 |

| BGA da Ultra-Fine (uBGA) | |

| Masu ɗaukar Chip marasa guba/CSP | |

| Kunshin Ba-Guba (QFN) Quad Flat | |

| Kunshin Flat Quad (QFP) | |

| Mai ɗaukar Filastik Chip Carrier (PLCC) | |

| SOIC | |

| Kunshin-On-Package (PoP) | |

| Karamin Kunshin Chip (Kyakkyawan Pitch zuwa 0.02mm/0.8 mil) | |

| Majalisar SMT mai gefe biyu | |

| wuri ta atomatik na Ceramic BGA, Plastic BGA, MBGA | |

| Cire & Sauyawa BGA's & MBGA's, ƙasa zuwa farar 0.35mm, har zuwa 45mm | |

| Gyaran BGA da Reball | |

| Cire Sashe da Sauyawa | |

| Cable da Waya | |

| Kunshin sashi | Yanke Tef, Tube, Reels, Reel Partial, Tray, Bulk, Sake Sassa |

| inganci | IPC Class II/IPC Class III |

| Sauran Ƙarfi | Bayanin DFM |

| Tsabtace Mai Ruwa | |

| Daidaitaccen sutura | |

| Ayyukan Gwajin PCB |

Gudanar da inganci

Inganci shine babban fifikonmu.PCB ShinTech yana da hanyar da aka yi niyya don tabbatar da cewa an samar da PCB ɗin ku kuma an haɗa su tare da matsakaicin inganci da daidaito.Babu wani abu a PCB ShinTech da aka bari ga dama.Muna aiki tuƙuru a kowane matakin aiki don tabbatar da cewa an ayyana kowane tsari kuma an rubuta umarnin aiki ta yadda za mu iya samar da samfura da ayyuka masu inganci iri ɗaya ga abokan cinikinmu.

1. Fahimtar tsammanin abokin ciniki da bukatun.

2. Ci gaba da ƙirƙira da sadar da sabbin dabi'u ga abokan ciniki.

3. Amsa ga koke-koken abokan ciniki da sauri.Idan muka fuskanci matsala, muna ɗaukar kowane irin wannan lamari a matsayin damar koyan abin da ba daidai ba, da yadda za mu hana sake faruwa.

4. Kafa tsarin kula da ingancin aiki mai kyau da inganta ingantaccen tsarin ci gaba.

Muna goyan bayan ingancin PCBs da PCBA ta hanyar shirya kayan aikin da suka dace, ta amfani da kayan aiki masu dacewa, siyan kayan da suka dace, aiwatar da ingantaccen aiki, da hayar da horar da ma'aikatan da suka dace.Kowane tsari yana tafiya ta hanyar matakan sarrafawa iri ɗaya tare da manufar ba wai kawai haɓaka haɓakawa don amfanin abokan cinikinmu ba amma tare da babban burin ci gaba da isar da ingantaccen samfurin da aka gina ga tsammanin abokin ciniki da ƙayyadaddun hukumar.

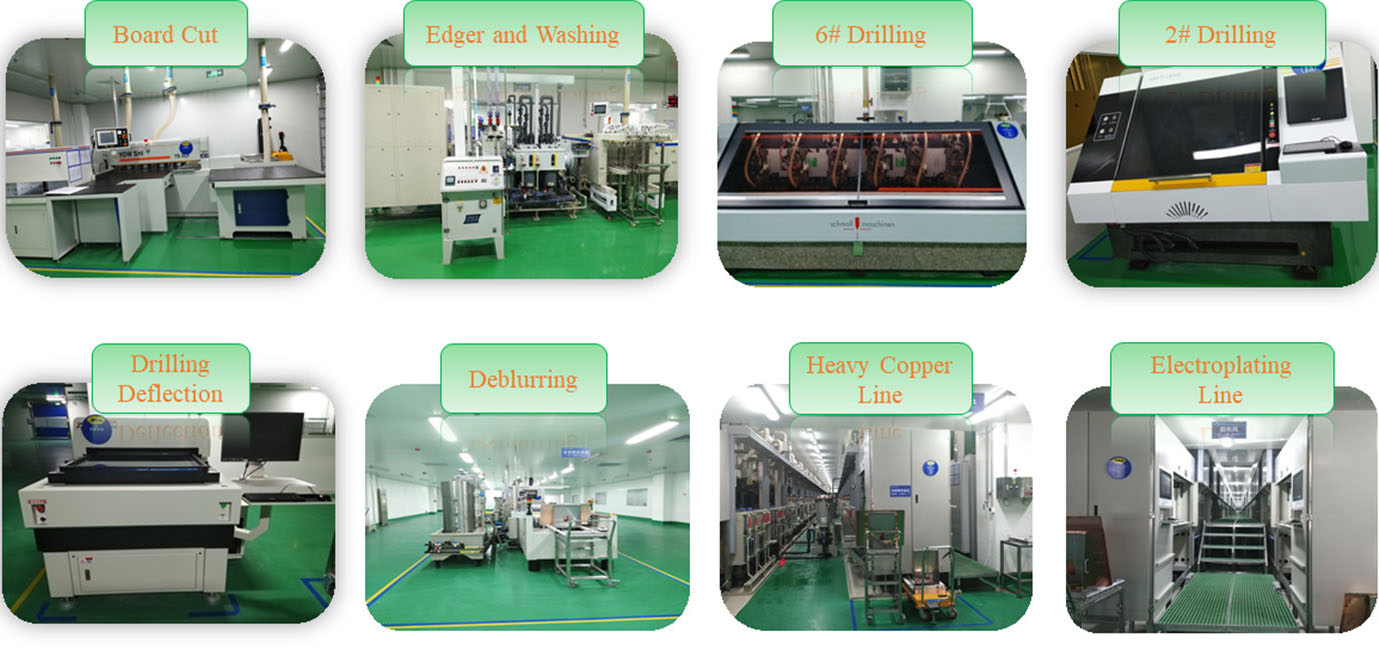

Kayan aiki na cikin gida da kayan aiki

Wuraren cikin gida na PCB ShinTech suna da ikon 40,000 m2kowane wata na ƙirƙira PCB.A lokaci guda PCB ShinTech yana da layin SMT 15 da layukan ramuka 3 a cikin gida.PCBs ɗinku ba a taɓa samar da mafi ƙanƙanta daga cikin manyan masana'antu ba.Don cimma ingantacciyar ingantaccen aiki daga taron PCB, muna ci gaba da saka hannun jari a sabbin kayan aiki waɗanda ke ba da izinin daidaitaccen daidaitaccen tsari don duk tsarin taro, gami da X Ray, manna solder, ɗauka da wuri da ƙari.

Horon ma'aikata

Kowane PCB ShinTech's masana'antu da taro wuraren yana da cikakken horar da sufeto, domin mu mafi muhimmanci burin shi ne isar da inganci.Horon masu aiki yana da mahimmanci.Wajibi ne kowane ma'aikaci ya duba allon allon yayin da suke tafiyar da ayyukansu, kuma muna tabbatar da cewa sun sami cikakken horo kuma sun sami ƙwarewar da suka dace.

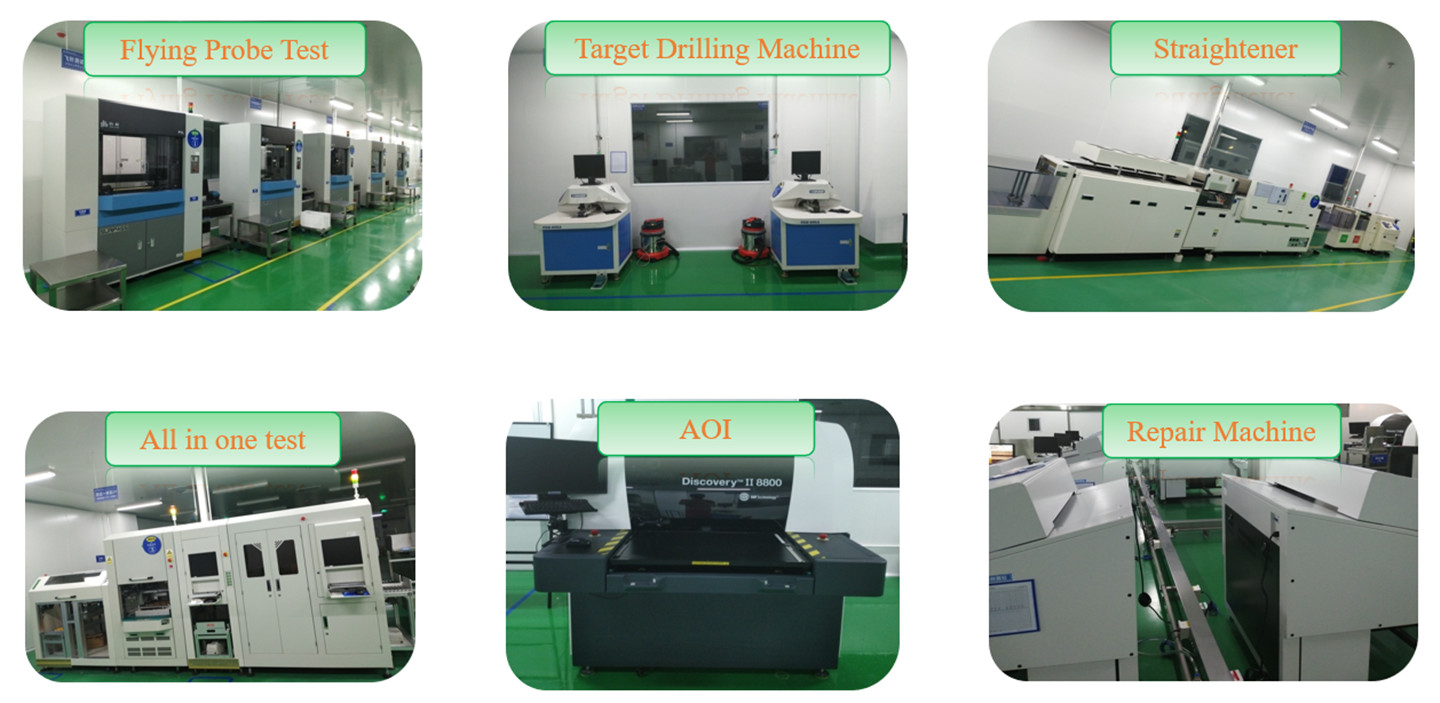

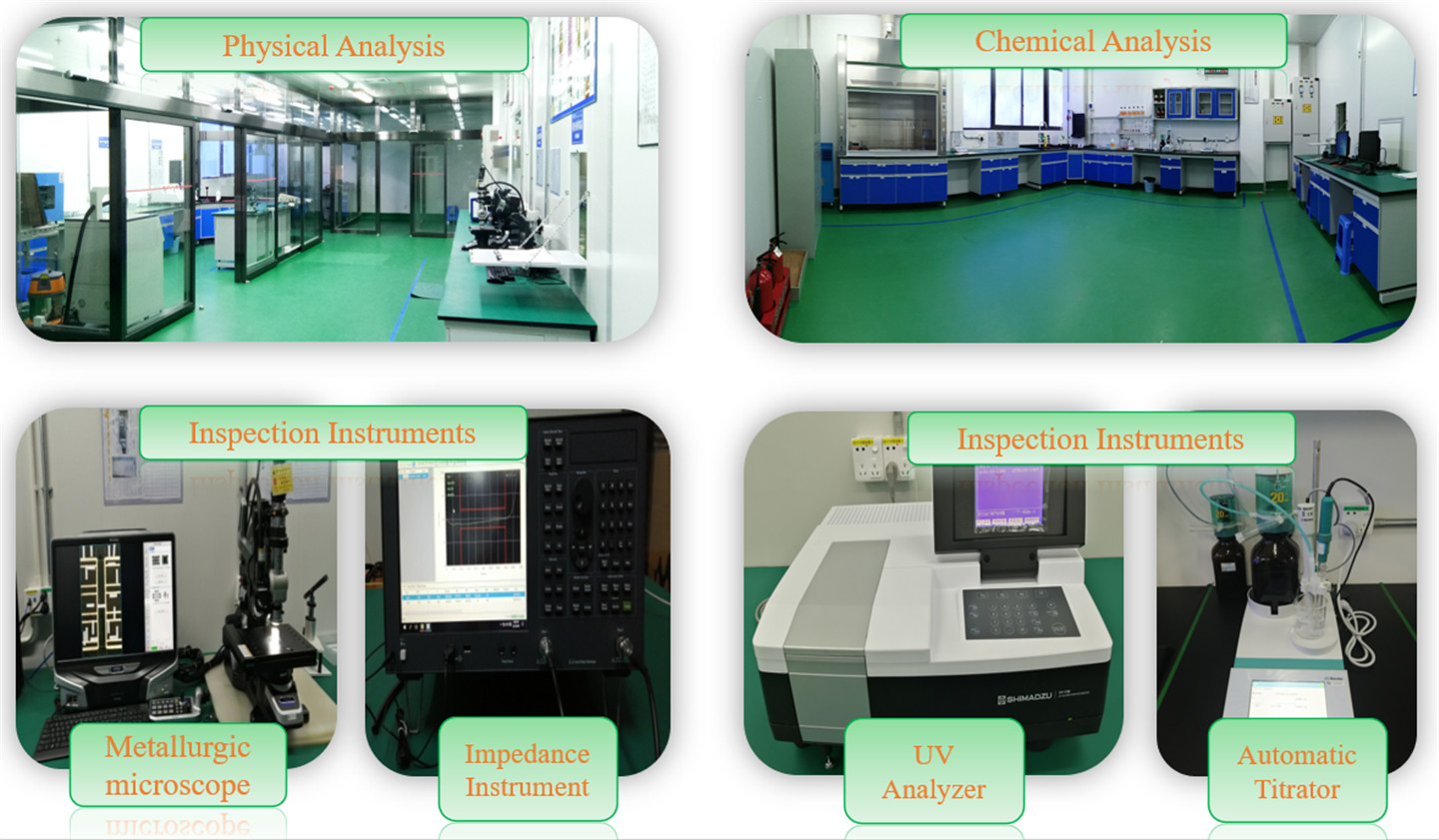

Dubawa da gwaji

Tabbas, dubawa da gwaji kuma suna haskakawa a cikin tsarin sarrafa ingancin PCB ShinTech.Muna amfani da waɗannan don tabbatar da cewa ayyukanmu suna gudana daidai.Waɗannan matakan suna ba ku ƙarin tabbacin cewa allon da kuka karɓa daidai ne da ƙirar ku kuma zai yi daidai tsawon rayuwar samfuran ku.Mun saka hannun jari a cikin kayan aiki na X-ray fluorescent, AOI, gwajin gwajin gardama, gwajin lantarki da sauransu don wannan dalili.Yawancin abokan ciniki ba su da albarkatun yin abubuwa a cikin gida.Muna ɗaukar alhakin tabbatar da cewa kowane abokin ciniki ya sami ainihin abin da suke buƙata.

An bayyana waɗannan matakan kamar yadda ke ƙasa.

BARE PCB BOARD FABRICATION

● Binciken gani na atomatik (AOI) & dubawa na gani

● Ƙwararriyar ƙira na dijital

● Ƙananan sassa

● Ci gaba da nazarin sinadarai na matakan rigar

● Bincike akai-akai game da lahani da gogewa tare da ayyukan gyarawa

● Gwajin lantarki yana cikin duk sabis

● Ma'auni don sarrafawa mai sarrafawa

● Polar Instruments software don ƙira na tsarin impedance sarrafawa da takardun shaida.

PCB Majalisar

● Bare allo da mai shigowa abubuwan dubawa

● Binciken farko

● Binciken gani na atomatik (AOI) & dubawa na gani

● Binciken X-ray lokacin da ake buƙata

● Gwajin aiki lokacin da ake buƙata

Kayayyaki da Kayayyaki

Wuraren cikin gida na PCB ShinTech suna da ikon 40,000 m2kowane wata na ƙirƙira PCB.A lokaci guda PCB ShinTech yana da layin SMT 15 da layukan ramuka 3 a cikin gida.PCBs ɗinku ba a taɓa samar da mafi ƙanƙanta daga cikin manyan masana'antu ba.Don cimma ingantacciyar ingantaccen aiki daga taron PCB, muna ci gaba da saka hannun jari a sabbin kayan aiki waɗanda ke ba da izinin daidaitaccen daidaitaccen tsari don duk tsarin taro, gami da X Ray, manna solder, ɗauka da wuri da ƙari.

2. PCBA

Takaddun shaida

Wuraren mu suna riƙe waɗannan takaddun shaida:

● ISO-9001: 2015

● ISO14001: 2015

● TS16949: 2016

● UL: 2019

● AS9100: 2012

● RoHS: 2015

Aiko da tambayar ku ko buƙatar faɗa mana asales@pcbshintech.comdon haɗawa da ɗaya daga cikin wakilan tallace-tallacenmu waɗanda ke da ƙwarewar masana'antu don taimaka muku samun ra'ayin ku zuwa kasuwa.